For over 85 years, maintenance-free, self-lubricating sliding bearings from DEVA have been proving themselves in innumerable industrial applications.

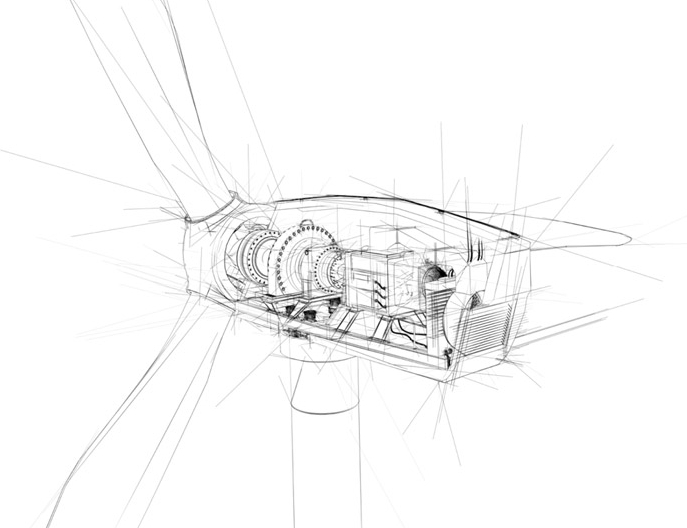

Our products can be found in large machines, in the construction and automotive industries, in wind turbines and hydroelectric power plants as well as in general mechanical engineering. Experienced teams of specialists are in action for you around the globe in order to develop, install, and look after your sliding bearing solution.

From design and installation to inspection, DEVA

is there by your side as your all-in-one service partner.

Our expert team is in action around the globe to get to know your application, to understand your requirements, and to offer you individual sliding bearing solutions.

And if any questions crop up in the process, we're always there for you.

Short distances, quick solutions!

Our vast experience means that we are not only experts as regards sliding bearings but also professional solution providers and process consultants.

Our specialist teams work on an equal footing with you in order to get to know your application, understand it, and guide it to success. The complexity of your project is irrelevant.

Benefit from our expertise, and let's talk in confidence about your next challenge.